CONTAINER CODE RECOGNITION

Standard Business Case

DO YOU HANDLE CONTAINERS AT YOUR BUSINESS?

There are tens of millions of containers stacked in depots or in transit around the world by sea, rail or road and Konica Minolta‘s Container Code Recognition solution helps track and identify them as they move around or are loaded onto vehicles.

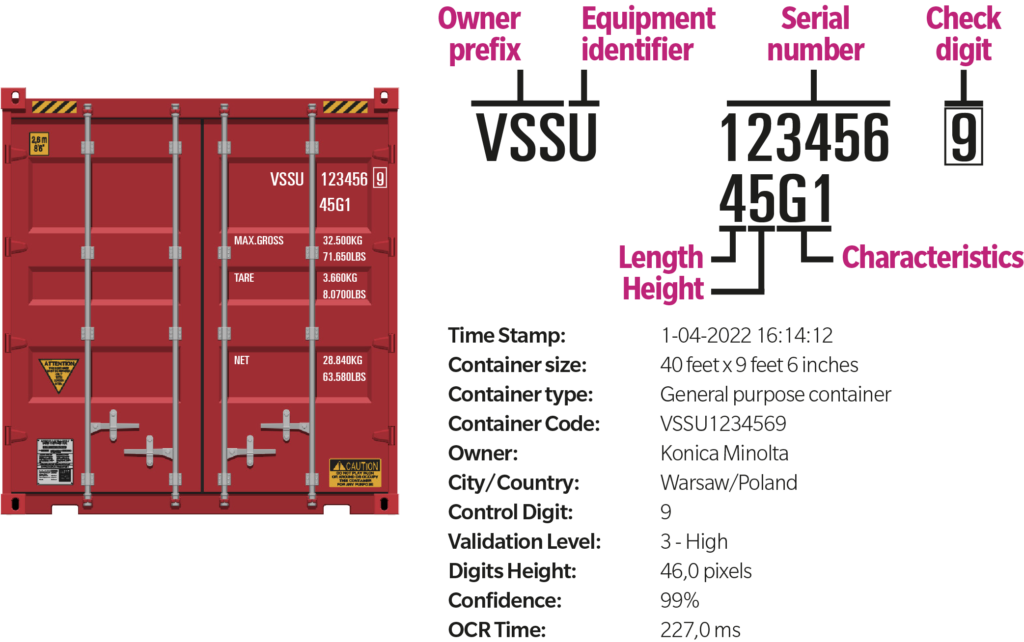

The Vaxtor OCR analytics running on board Mobotix Series 7 camera read both horizontal and vertical codes and reports the container code number along with other metadata such as time, date, GPS position, confidence etc. The data provided includes the owner code, owner city, container type and dimensions to aid tracking and identification.

Our solution provides automatic detection and logging of containers on entry, between zones, during processes and on exit from Air and Sea ports automating and streamlining processes, ensuring Health & Safety, insurance and logistical chain management. Together creating efficient and secure transportation networks of the highest performance.

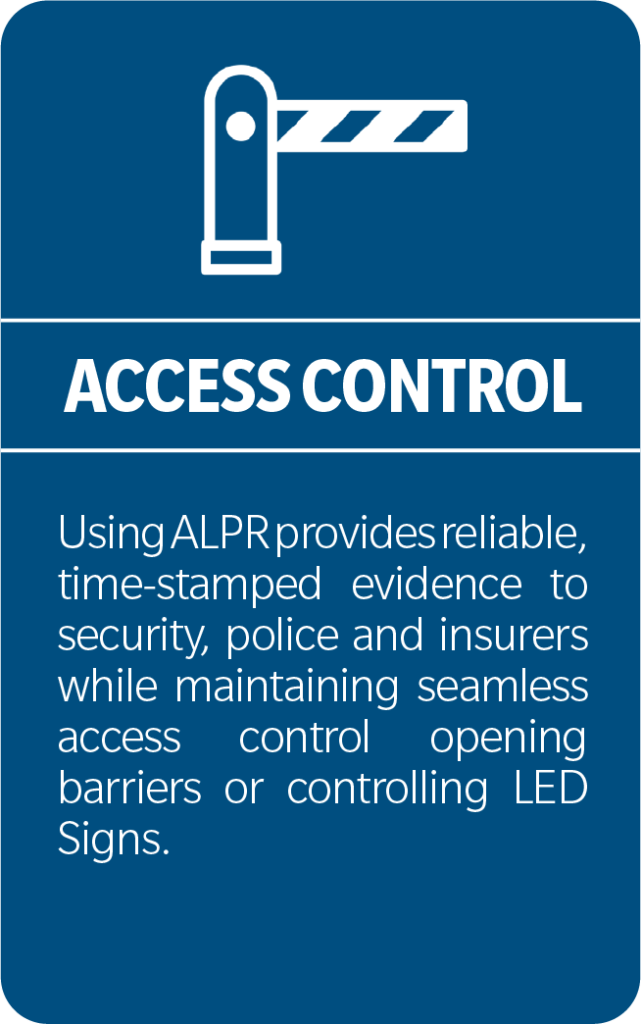

How does it work?

Optical character recognition (OCR) lets you turn scanned images into text so you can turn paper-based documents into editable, searchable, digital documents. This can help reduce the amount of physical space required to store documents and can dramatically improve workflows involving those documents. It reduces the risk of lost or misfiled documents and, in many cases, it eliminates the need to manually process documents or rekey information, which can result in errors. And it can reduce the costs of manual handling.

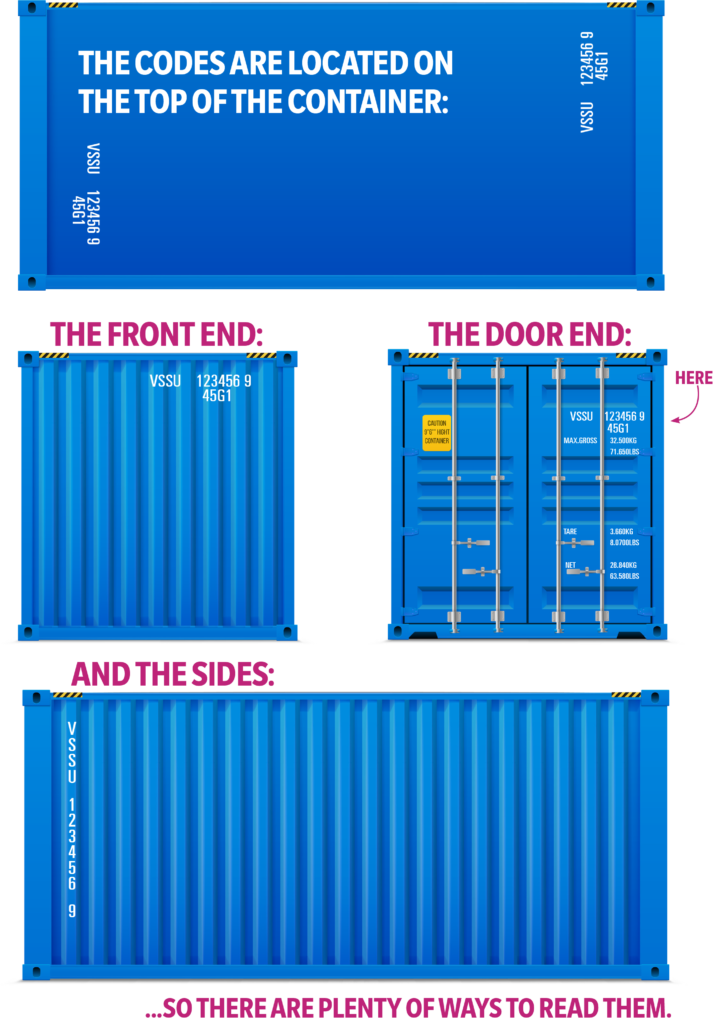

ISO 6346 CONTAINER CODE READING = GLOBAL SOLUTION

FEATURES & BENEFITS

HIGH RATE

Recognition rate above 99%!

MULTI-DIRECTION TEXT SUPPORT

Recognition of both horizontal and vertical container ISO 6346 codes.

HIGH SPEED OPERATION

The code recognition is virtually instantenous, even without having to stop the truck.

MULTI-MODE OPERATION

•Triggered mode: used in weigh bridge, crane and access control scenarios.

•Free-Flow mode: continuous mode – all codes read & reported in real time.

CONTROL DIGIT VALIDATION

VaxOCR Container can utilise and report the control digit and code read variance.

COMPLEX SCENARIO SUPPORT

Directional filtering, Regions Of Interest enabling filtering and actions using polygons, inclusions, exclusions and direction.

EMBEDDED ANALYTICS

The Container Code Recognition App performs the analytics on-board the Mobotix series 7 cameras. Optionally, an Android mobile application could be used.

EFFICIENCY INCREASE

The implementation of the container code recognition solution can increase the operational efficiency of the port/cargo lot/docks to even as much as 75%.

RESULTS IN REAL TIME

WHAT ARE THE APPLICATIONS?

What is YOUR return of investment?

Implementation of the container code recognition brings a variety of benefits. Depending on the structure and size of the facility, each scenario helps to optimize processes and therefore save money. Below you can find some scenarios that are most commonly described by our customers:

Efficiency boost

Typically, arrival of trucks carrying containers generates a lot of manual work. First, the guard at the main gate would have to check the license plates of the truck, confirm the container number and then either input all that data to some kind of system or -even worse- write it down in a paper log or a notebook. That takes a lot of time and effort, not to mention the risk of losing the paper log.

The implementation of the Container Code Recognition solution makes the entire process automatic, fast and seamless. The container codes (and license plates if needed) are recognized by the camera instantly, stored in a safe database with a timestamp and can be easily searched by filters and connected with a video recording of the entire process.

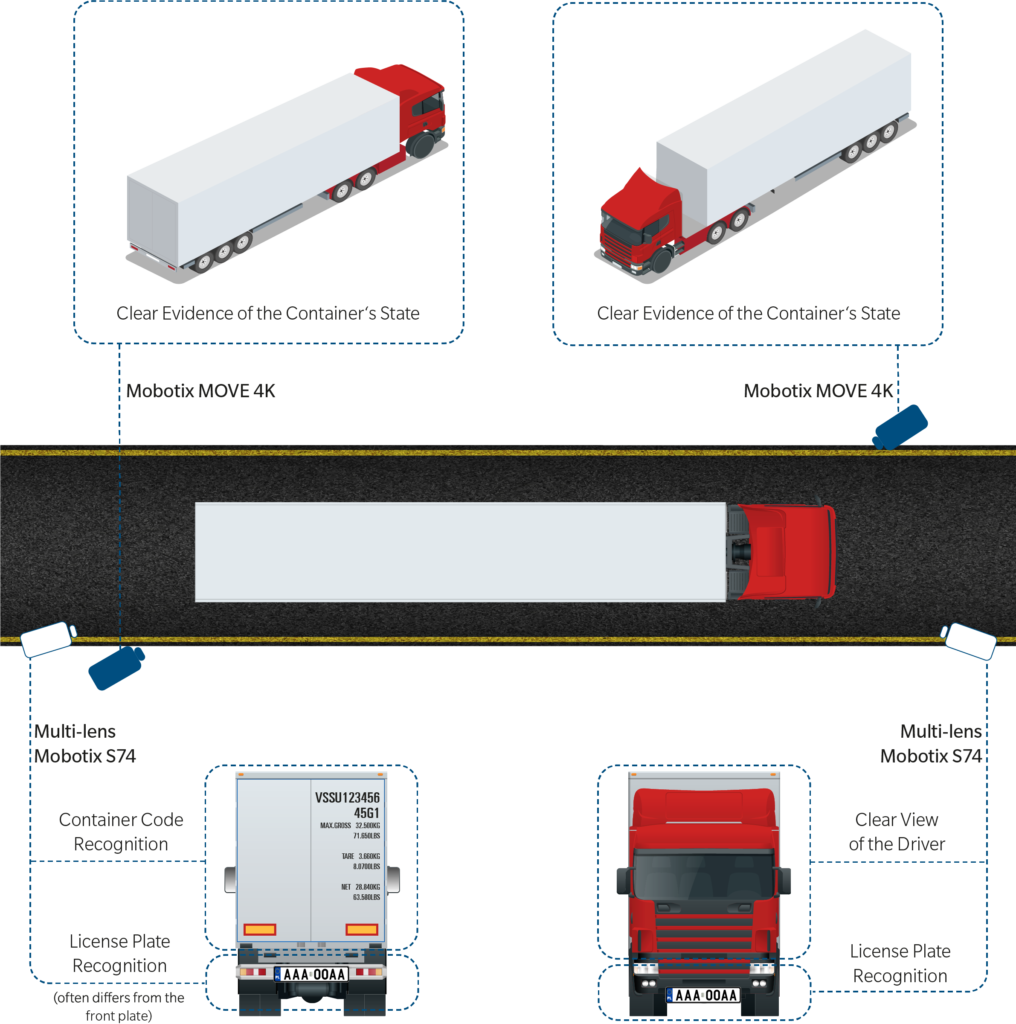

Insurance claims

Installing additional cameras to the system can provide further benefits to the property owner and the customers. One of the issues that often occurs while handling containers are damage claims. If a customer claims the container has been damaged on your premises, it may become a long battle of word-against-word. This significantly influences the efficiency of your business (each case needs to be manually handled by an employee), your costs (increased insurance costs for false claims, additional employees, lost business) and your good reputation. The solution is easy and cost-efficient- upgrading the Container Code Recognition system with additional cameras that will cover all container sides. That way, by entering a specific container number or a license plate of the truck in question, a clear video proof of the container‘s state at entry and exit can be retrieved instantly, exported and presented to the customer. Solving disputes will become virtually instantaneous, saving a considerable amount of time, preventing insurance fraud (therefore directly saving money) and stopping false claims in the future.

Container tracking

Keeping track of each container‘s location is a major challenge, especially across large perimeters. On one side, paperwork not only takes time and could get lost or damaged, on the other – even having a computer system is vulnerable to human error. Searching for a specific container might take a considerable amount of time, usually involving numerous personnel.

Having the Container Code Solution installed in a distributed manner will collect each container’s “last seen” location that will shorten the search time tremendously. In addition, user can track specific container’s route within the property.

Container tracking on cranes

In order to provide the most precise location of a container, many logistics centers decide to install cameras on the cranes lifting the containers. The Container Code Recognition solution collects all the metadata but also allows to send the data further to third party systems which may analyze it or combine with additional external information (GPS location etc).

SOLUTION PACKAGES SELECTION

BASIC SOLUTION

EXTENDED SOLUTION

FULL SOLUTION

WHERE TO INSTALL THE CAMERAS